Enhanced Material Processing Versatility

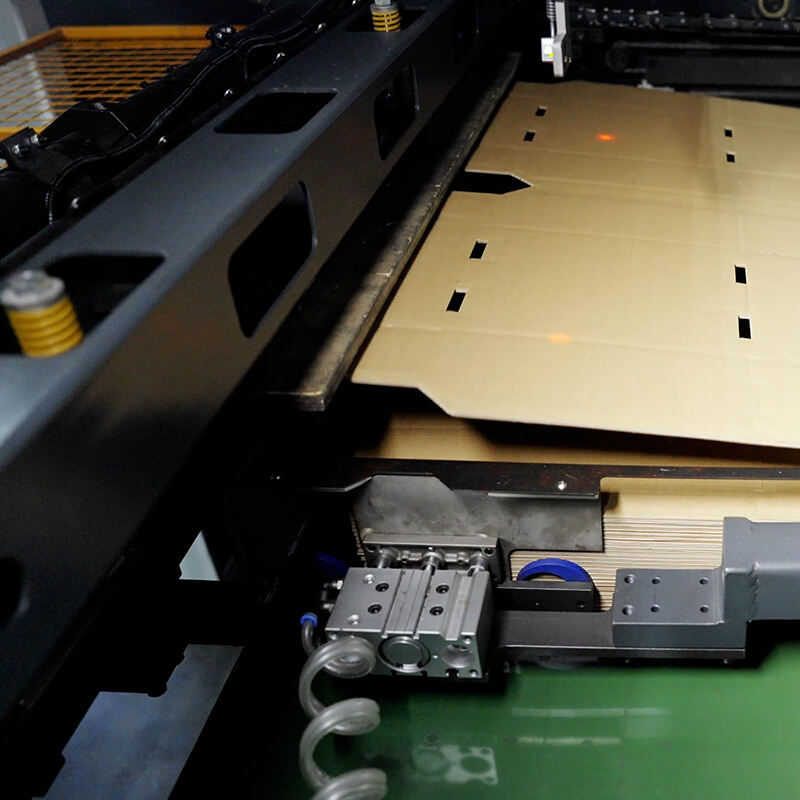

The exceptional material processing versatility of flatbed die cutting machines sets them apart in the manufacturing landscape. These machines excel at handling an extensive range of materials with varying properties and thicknesses, from delicate paper to rigid plastics and thin metals. The precisely controlled cutting mechanism ensures clean edges and accurate dimensions regardless of material type, while adjustable pressure settings prevent material damage or distortion. This versatility extends to the ability to perform multiple operations in a single pass, including cutting, scoring, perforating, and embossing, making the machine invaluable for complex manufacturing processes. The robust design accommodates both small precision work and large format materials, providing flexibility for diverse production requirements.