جدید تیار کردہ صنعت میں ڈائی کٹنگ کی ٹیکنالوجی کا ارتقاء

پیداواری منظر نامہ تیزی سے تبدیل ہو رہا ہے، جس میں فلیٹ بیڈ ڈائی کٝٹر جدید تقاضوں کی بنیاد پر ٹیکنالوجی اہم کردار ادا کر رہی ہے۔ ان بہت سے مقاصد کے مشینوں نے صنعتوں کے لحاظ سے درستگی والی کٹنگ، اسکورنگ، اور کریزنگ آپریشنز کے طریقہ کار کو مکمل طور پر بدل دیا ہے۔ جیسے جیسے ہم 2025 کی طرف بڑھ رہے ہیں، ویسے ویسے مارکیٹ میں اپنے مقابلے کے فوائد برقرار رکھنے کے خواہشمند کاروباروں کے لیے جدید فلیٹ بیڈ ڈائی کٹر سسٹمز کو اپنانا مزید اہمیت اختیار کر چکا ہے۔

آج کے فلیٹ بیڈ ڈائی کٹر مشینوں میں پیچیدہ خودکار خصوصیات، بہتر شدہ درستگی کے کنٹرولز اور بہتر مواد کی افزائش کی صلاحیتیں شامل ہیں۔ ان ترقیات نے مختلف صنعتی شعبوں میں انہیں ناقابلِ گُریز اوزار بنادیا ہے، جس سے کاروباری ادارے بہتر معیار حاصل کرنے کے ساتھ ساتھ زیادہ پیداواری کارکردگی برقرار رکھ سکتے ہیں۔

پیکیجنگ اور کرّوگیٹڈ صنعت کے استعمالات

حسبِ ضرورت پیکیجنگ کے حل

پیکیجنگ کی صنعت فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی کا بنیادی صارف رہی ہے، جس میں حسبِ ضرورت پیکیجنگ کے حل کی مانگ میں اضافہ ہوا ہے۔ صنعت کار ان مشینوں کو کرّوگیٹڈ مواد میں درست کٹنگ اور اسکورنگ پیدا کرنے کے لیے استعمال کرتے ہیں، سادہ باکسز سے لے کر پیچیدہ ریٹیل ڈسپلے تک تیار کرتے ہیں۔ مختلف مواد کی موٹائی کو سنبھالنے اور مستقل معیار برقرار رکھنے کی فلیٹ بیڈ ڈائی کٹر کی صلاحیت پیکیجنگ کمپنیوں کے لیے ناقابلِ قدر ثابت ہوتی ہے جو مختلف کلائنٹ کی ضروریات کو پورا کرتی ہیں۔

اب ترقی یافتہ فلیٹ بیڈ ڈائی کٹر سسٹمز میں خودکار فضلہ اخراج کے نظام اور تیزی سے ٹولز تبدیل کرنے کی سہولت شامل ہے، جو پیکیجنگ کے صنعت کاروں کو مختلف ڈبے کے ڈیزائن کے درمیان تیزی سے تبدیلی کرنے کی اجازت دیتی ہے۔ چونکہ برانڈز اپنی مصنوعات کے لیے زیادہ ماہرانہ پیکیجنگ حل کا مطالبہ کر رہے ہیں، اس لیے یہ لچک ضروری ہو گئی ہے۔

ریٹیل ڈسپلے کی تیاری

خریداری کے مقام پر ڈسپلے پیکیجنگ شعبے کے اندر ایک اور اہم درخواست کی نمائندگی کرتے ہیں۔ فلیٹ بیڈ ڈائی کٹر مشینیں دکانوں کے ڈسپلے کے لیے ضروری پیچیدہ ڈیزائن تیار کرنے میں بہترین کارکردگی کا مظاہرہ کرتی ہیں۔ درست گھسنے اور نشان زدگی کی صلاحیتیں یقینی بناتی ہیں کہ ڈسپلے ساختی طور پر مضبوط اور بصارتی طور پر دلکش دونوں ہیں، جو ریٹیل مارکیٹنگ مہمات کے سخت معیارات کو پورا کرتے ہیں۔

جدید فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی کے ساتھ ڈیجیٹل ڈیزائن سسٹمز کے ادراج نے پیچیدہ ڈسپلے یونٹس کی تیاری کو آسان بنایا ہے، جس سے سیٹ اپ کے وقت میں کمی اور مواد کے ضائع ہونے کی حد تک کمی واقع ہوئی ہے۔

موٹر گاڑیوں کے حصوں کی تیاری

اندر کے اجزاء کی تیاری

خودکار صنعت نے مختلف اندرونی اجزاء کی تیاری کے لیے فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی کو اپنایا ہے۔ ڈیش بورڈ کی عارضی سے لے کر فرش کے قالین تک، یہ مشینیں مواد کو بالکل درست خصوصیات کے مطابق کاٹتی ہیں۔ فلیٹ بیڈ ڈائی کٹر سسٹمز کی مسلسل اور قابل اعتماد کارکردگی کی بدولت اجزاء خودکار صنعت کے سخت معیارات پر پورا اترتے ہیں۔

خودکار درخواستوں کے لیے ضروری درست رواداری کو برقرار رکھتے ہوئے پیداواری موثریت میں اضافہ کرتے ہوئے جدید فلیٹ بیڈ ڈائی کٹر مشینوں کی متعدد مواد کی تہوں کو ایک ساتھ سنبھالنے کی صلاحیت کو خاص طور پر صنعت کار قدر کی نظر سے دیکھتے ہیں۔

گیسکٹ اور سیل کی تیاری

خودکار گیسکٹس اور سیلز کو نمایاں درستگی اور مسلسلی کی ضرورت ہوتی ہے۔ اس درخواست میں فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی بہترین کارکردگی کا مظاہرہ کرتی ہے، وہ اجزاء تیار کرتی ہے جو سخت معیاری ضروریات کو پورا کرتے ہیں۔ مختلف مواد جیسے ربڑ سے لے کر کمپوزٹ مواد تک کو کاٹنے کی مشینوں کی صلاحیت انہیں گیسکٹ تیاری کے آپریشنز میں ناقابل تبدیل بناتی ہے۔

جدید فلیٹ بیڈ ڈائی کٹر سسٹمز میں آپٹیکل رجسٹریشن سسٹمز شامل ہوتے ہیں، جو جستک پیداوار میں بہترین محاذِم داری یقینی بناتے ہیں اور مواد کے ضائع ہونے کو کم کرتے ہیں۔

الیکٹرانکس صنعت کے استعمالات

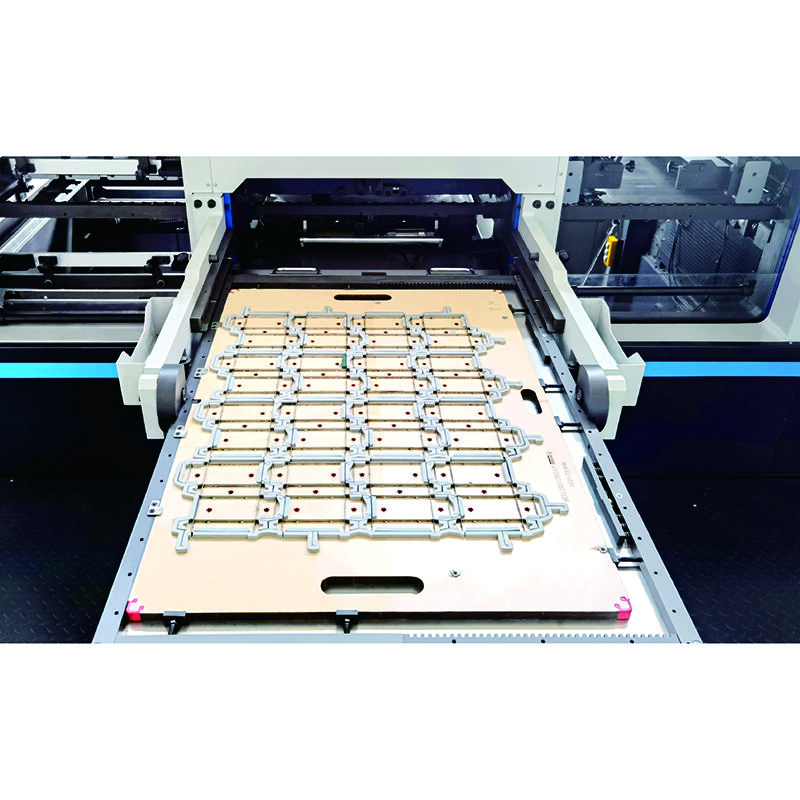

سرکٹ بورڈ کمپونینٹ کی پیداوار

الیکٹرانکس کی صنعت سرکٹ بورڈ اسمبلی میں استعمال ہونے والے مختلف اجزاء کی تیاری کے لیے فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی پر شدید انحصار کرتی ہے۔ یہ مشینیں الیکٹرانک ڈیوائسز کی تیاری کے لیے ضروری عایق مواد، چپکنے والے اجزاء اور حفاظتی عناصر کو درستگی سے کاٹتی ہیں۔ جدید فلیٹ بیڈ ڈائی کٹر سسٹمز کی بالا درستگی خودکار اسمبلی عمل کے لیے اجزا کے ابعاد میں مسلسل یکسانیت یقینی بناتی ہے۔

جنبہ شدہ سینسر سسٹمز اور کمپیوٹر کنٹرولز ان مشینوں کو الیکٹرانک اجزاء کے لیے درکار تنگ رواداری برقرار رکھنے کی اجازت دیتے ہیں، جبکہ خودکار مواد کی اشیاء کا خطرہ آلودگی کو کم کرتی ہے۔

غیر معمولی الیکٹرانکس پیکیج

کنسیومر الیکٹرانکس کی پیکیجنگ درستگی اور خوبصورتی دونوں کی متقاضی ہوتی ہے۔ فلیٹ بیڈ ڈائی کٹر مشینیں جدید پیکیجنگ حل پیدا کرتی ہیں جو حساس الیکٹرانک آلات کی حفاظت کے ساتھ ساتھ دلکش پیش کش فراہم کرتی ہیں۔ پیچیدہ کٹس اور اسکورز تیار کرنے کی صلاحیت پیکیجنگ کے انقلابی حل ڈیزائن کرنے کی اجازت دیتی ہے جو 'ان باکسنگ' کے تجربے کو بہتر بناتی ہے۔

فلیٹ بیڈ ڈائی کٹر سسٹمز میں اسمارٹ خصوصیات کا اظتحال الیکٹرانکس کی تیز رفتار منڈی میں ضروری ڈیزائن میں تبدیلیوں کو فوری طور پر ممکن بناتا ہے۔

پرنٹنگ اور خصوصی کاغذ کی تیاری

پیٹرن کٹنگ آپریشنز

پرنٹنگ اور خصوصی کاغذ کی صنعت مختلف قسموں اور موٹائی والے کاغذات میں درست نمونہ کاٹنے کے لیے فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی کا استعمال کرتی ہے۔ یہ مشینیں لیبلز اور کارڈز جیسی اشیاء کی پیداواری کارکردگی کو نمایاں طور پر بہتر بنانے کے لیے کاغذ کی متعدد تہوں کو ایک ساتھ سنبھالنے میں ماہر ہیں۔ جدید فلیٹ بیڈ ڈائی کٹر سسٹمز میں جدید مواد کی حراست کی خصوصیات شامل ہوتی ہیں جو کاٹنے کے دوران کاغذ کی شکل بگاڑنے سے روکتی ہیں۔ فلیٹ بیڈ ڈائی کٹر مشینوں کے ساتھ ضم شدہ ڈیجیٹل نمونہ مینجمنٹ سسٹمز تیزی سے نمونہ تبدیل کرنے اور خصوصی پرنٹنگ میں کاغذ کے مواد کے بہترین استعمال کو یقینی بناتے ہیں، جس سے فضلہ کم ہوتا ہے۔

اعلیٰ جِلد کارڈ بورڈ اور باریک کاغذ کے اطلاقات

اعلیٰ درجے کی کاغذ کی مصنوعات، بشمول مضبوط گتے اور نازک باریک کاغذ کے ذخائر، بہترین درستگی اور احتیاط سے تبادلہ کرنے کی ضرورت ہوتی ہیں۔ فلیٹ بیڈ ڈائی کٹر مشینیں ان مخصوص درخواستوں کے لیے درکار درستگی اور مسلسل معیار فراہم کرتی ہیں۔ مختلف کاغذی مواد کو پروسیس کرنے کی صلاحیت جبکہ درست ابعاد برقرار رکھنے کی وجہ سے یہ مشینیں اس بڑھتے ہوئے شعبے میں ناگزیر ہو چکی ہیں۔ جدید فلیٹ بیڈ ڈائی کٹر سسٹمز میں اب خصوصی ہینڈلنگ سسٹمز شامل ہیں جو حساس اور موٹے کاغذی مواد کے لیے خصوصی طور پر ڈیزائن کیے گئے ہیں، جو مختلف قسم کے کاغذ کی اقسام میں بہترین نتائج کو یقینی بناتے ہیں۔

طبی سامان کی تیاری

طبی پیکیجنگ کی پیداوار

میڈیکل صنعت سٹرائل پیکیجنگ کے اجزاء کی تیاری کے لیے فلیٹ بیڈ ڈائی کٹر ٹیکنالوجی پر انحصار کرتی ہے۔ یہ مشینیں میڈیکل پیکیجنگ کے لیے درکار سخت صفائی کے معیارات برقرار رکھتی ہیں جبکہ درست کٹ اور سیلز کو یقینی بناتی ہیں۔ فلیٹ بیڈ ڈائی کٹر سسٹمز کی مسلسل اور قابل اعتماد کارکردگی میڈیکل پیکیجنگ کے ضوابط کے مطابق رہنے کے لیے نہایت اہم ہے۔

جدید مشینیں صاف ماحول (کلین روم) کے مطابق خصوصیات اور مواد کی نگرانی کے نظام شامل کرتی ہیں جو میڈیکل تیاری کی درخواستوں کے لیے ضروری ہیں۔

میڈیکل اجزاء کی تیاری

زخم کے پٹیوں سے لے کر تشخیصی ٹیسٹ کے اجزاء تک مختلف میڈیکل اجزاء کے لیے درست کٹنگ اور شکل دینے کے آپریشنز کی ضرورت ہوتی ہے۔ فلیٹ بیڈ ڈائی کٹر مشینیں ان درخواستوں میں بہترین کارکردگی کا مظاہرہ کرتی ہیں، میڈیکل مصنوعات کی تیاری کے لیے درکار درستگی اور صفائی فراہم کرتی ہیں۔ نازک مواد کو سنبھالنے کی صلاحیت جبکہ سخت معیارِ معیار برقرار رکھنا ان مشینوں کو میڈیکل سامان کی تیاری میں ناقابل تبدیل بناتی ہے۔

اعلیٰ درجے کے کنٹرول سسٹمز پیداواری عمل کے دوران معیار کو مستحکم رکھنے کو یقینی بناتے ہیں، جو طبی اجزاء کی تیاری کے لیے نہایت ضروری ہے۔

اکثر پوچھے گئے سوالات

فلیٹ بیڈ ڈائی کٹر مشینوں کی دیکھ بھال کے لیے کیا تقاضے ہوتے ہی ہیں؟

فلیٹ بیڈ ڈائی کٹر مشینوں کی باقاعدہ دیکھ بھال میں کٹنگ کی سطحوں کی روزانہ صفائی، کٹنگ ڈائیز کا باقاعدہ معائنہ اور تبدیلی، حرکت پذیر اجزاء کی چکنائی اور کنٹرول سسٹمز کی کیلیبریشن شامل ہے۔ مشین کی بہترین کارکردگی اور لمبی عمر کو یقینی بنانے کے لیے پیشہ ورانہ دیکھ بھال کی خدمات ہر تین ماہ بعد مقرر کرنی چاہئیں۔

ڈیجیٹل کنٹرول فلیٹ بیڈ ڈائی کٹر کی کارکردگی میں بہتری کیسے لا سکتے ہیں؟

ڈیجیٹل کنٹرول فلیٹ بیڈ ڈائی کٹر کی کارکردگی میں بہتری لانے کے لیے کٹنگ کے پیرامیٹرز کی درست ترتیب، خودکار مواد کی انتظامیہ، اور ڈیزائن سافٹ ویئر کے ساتھ انضمام کی سہولت فراہم کرتے ہیں۔ ان خصوصیات کی وجہ سے سیٹ اپ کے وقت میں کمی آتی ہے، فضلہ کم ہوتا ہے، اور پیداواری عمل کے دوران معیار میں استحکام رہتا ہے۔

فلیٹ بیڈ ڈائی کٹر کے انتخاب کرتے وقت کن عوامل پر غور کرنا چاہیے؟

اہم نکات میں پیداواری حجم کی ضروریات، مواد کی اقسام جنہیں سنبھالنا ہو، درکار کٹنگ کی درستگی، دستیاب فرش کی جگہ، خودکار نظام کی ضروریات، اور موجودہ نظاموں کے ساتھ انضمام کی صلاحیت شامل ہیں۔ نیز، تیار کنندہ کی سپورٹ سروسز، اسپیئر پارٹس کی دستیابی، اور ملکیت کی کل لاگت پر غور کریں۔