Me kalimin e industrisë së printimit komercial nga „prodhimi masiv" te „dorëzimi i saktë", cilësia e çdo operacioni para-printimi varet nga suksesi i produktit përfundimtar në treg. Makineritë industriale për prerjen e fletëve, si një pjesë kritike, bëjnë më shumë se thjesht funksionin bazik të konvertimit të rrotullave të formatit të madh letre në fletë standarde. Ata janë të rëndësishëm për cilësinë operative të një fabrike printimi, duke pasur ndikim thelbësor si në saktësinë dimensionale ashtu edhe në efikasitetin e prodhimit.

Prerësit kryesorë të fletës janë bërë plotësisht inteligjentë. Një shembull është prerësi me saktësi të lartë i letrës, i cili garanton një saktësi prerjeje prej ±0,1 mm për stokqe me peshë 100–1000 g/m². Kjo mundësi zgjidh problemin e deshikimit të imazhit, i cili është i zakonshëm në paketimin premium (p.sh., për verëra, duhan, dhe çanta luksoze), duke reduktuar ndjeshëm normat e humbjeve dhe duke i ndihmuar prodhuesit të kthejnë letren e kursyer direkt në kursime kushtesh. Ky avantazh është veçanërisht i rëndësishëm kur përpunohen materiale me vlerë të lartë si letra speciale të importuara, stokqe me relief dhe tabela luksoze të arta/sihter, ku çdo milimetër saktësie ka një ndikim direkte në fitimin përfundimtar.

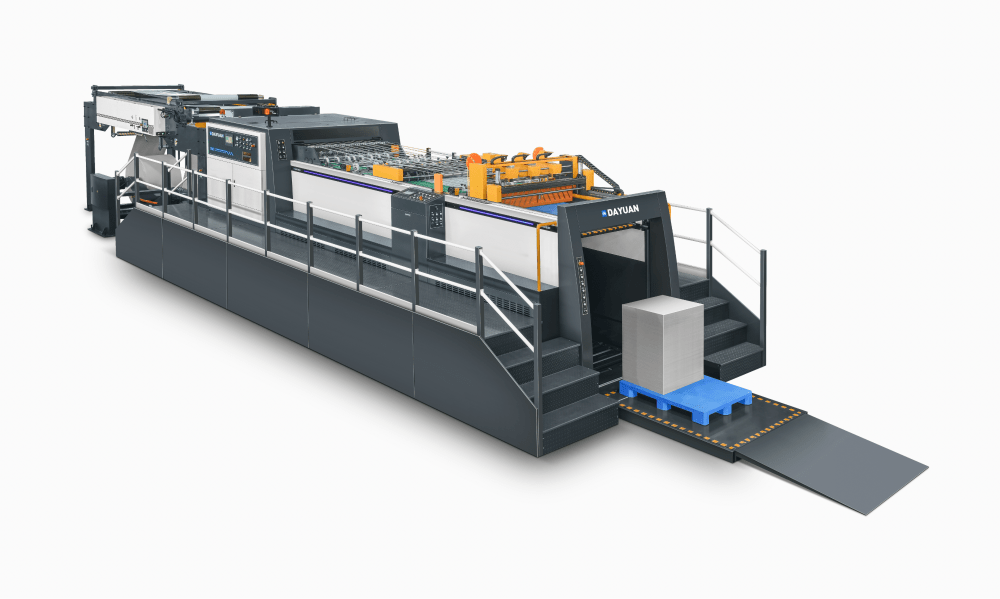

Për të plotësuar kërkesat praktike të prodhimit, Dayuan ka krijuar një gjeneratë të re prerësish letre rrotulluese. Seria SMC-ZH nxit standarde të reja me arritje thelbësore në tri fusha vendimtare:

1. Teknologjia rotative e fletëzimit

Kthetrës i dyfishtë spiral (patentë shpikje) i integruar eliminon bllokimet dhe kapjet e letrës në burimin e tyre gjatë funksionimit me shpejtësi të lartë. Kjo bashkëlidhet me një sistem patentë përkatës të thithjes që heq nevojën e rullave të shtypjes, duke siguruar që letra e lartë cilësie të procesohet pa dëmtuar skajet, pa gërime në sipërfaqe, pa brirë ose pluhur.

2. Mundësia e Operimit të Automatizuar

Sistemi ofron një rrjedhë të plotë automatike pune nga rula deri te fleta. Pas hyrjes së parametrave të punës, ai kryen regjistrim automatik, kundër-lakimi, prerje, gdhendje, presje dhe ndërrues automatik palete me një klikim. Rregullimi real-kohor i gjatësisë së prerjes lejon kalime të shpejta të porosive, duke eliminuar plotësisht vendosjet e ngadalta dhe manuale të makinave konvencionale.

3. Prodhim i Vazhdueshëm me Shpejtësi të Lartë

Makina trajton rrotulla me diametër deri në 1800 mm dhe gjerësi 1100–1900 mm, duke prodhuar pirgje deri në 1600 mm të larta me shpejtësi maksimale prerjeje prej 330 m/min (540 prerje/min). E integruar me një ndarës automatik, një ndërrues automatik paletash dhe një pajisje të pandërprerë për dorëzimin e letrës për perde, ajo zvogëlon ndjeshëm ndërhyrjen manuale. Me një plan urbanistik të optimizuar të impiantit, makina për prerjen e fletëve të letrës mund të funksionojë në sinkron me printerët dixhitalë me shpejtësi të lartë, duke maksimizuar efikasitetin e përgjithshëm të linjës së prodhimit.

Në krahasim me rrjedhat konvencionale të punës, presjet inteligjente të letres Dayuan bëjnë më tepër se thjesht të reduktojnë humbjen e letrës: ato garantojnë fletë tërthore me kënde të sakta dhe pa bisht, që sigurojnë ushqim tërheqës për shtyp, duke parandaluar regjistrimet e gabuara, bllokimet dhe dëmtimin e mëtejshëm të materialit. Kjo metodë eliminohet scrap-in në burim.

Investimi në një prerëse me saktësi të lartë ka bërë që kjo të jetë një zgjedhje strategjike e rëndësishme për përmirësimin e cilësisë së printimit, optimizimin e përdorimit të materialeve dhe sigurimin e cikleve të besueshme të dorëzimit. Aftësitë integruara të prerëseve automatike të fletave në precizion, automatizim dhe shpejtësi kthehen direkt në një fitim të vërtetë dhe të besueshëm për bizneset e printimit.

Me ekspertizë të thellë në fazën para-printimit dhe pas-printimit, Dayuan ofron këshilla praktike dhe zgjidhje të personalizuara për t'ju ndihmuar të ballafaqoheni me kërkesat komplekse të prodhimit. Ne bashkëpunojmë me ju për të optimizuar proceset, për të maksimizuar produktivitetin dhe për të nxitur rentabilitetin, pa marrë parasysh çfarë do të sjellë e ardhmja.

Lajme të nxehta

Lajme të nxehta 2025-12-30

2025-12-25

2025-11-27

2025-11-07

2025-10-09

2025-09-28