سیستمهای کنترل دقت پیشرفته

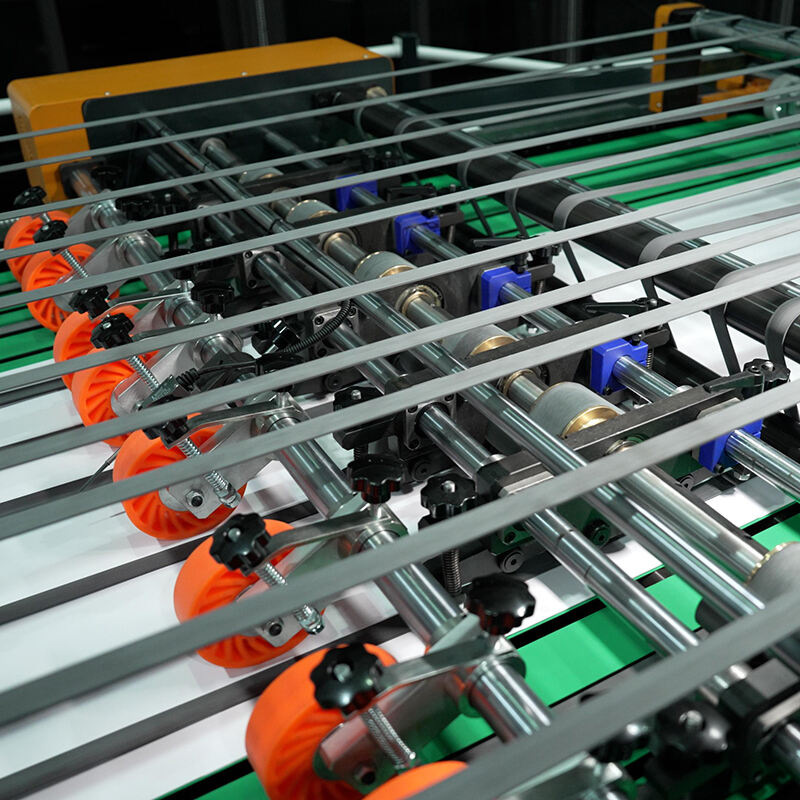

ماشینهای مدرن برگ کردن کاغذ دارای سیستمهای کنترلی حالت اول هستند که نشاندهنده یک پیشرفت قابل توجه در پردازش دقیق کاغذ است. این سیستمها از موتورهای سروی پیشرفته و کنترلرهای الکترونیکی استفاده میکنند که مشخصات برش دقیق را طی کل دوره تولید حفظ میکنند. توانایی نظارت در حین واقعه اجازه میدهد تغییرات فوری انجام شود تا ابعاد برگها به صورت ثابت حفظ شوند، با تغییرات معمول کمتر از 0.5 میلیمتر. سیستمهای کنترل نیز دارای رابطهای لمسی هوشمند هستند که به عملیاتگران اجازه میدهد به راحتی پارامترهای برش را برنامهریزی و تنظیم کنند، زمان آمادهسازی را کاهش دهند و منحنی یادگیری برای عملیاتگران جدید را حداقل کنند. ادغام با سیستمهای کنترل کیفیت امکان نظارت مستمر بر ابعاد برگ و تنظیمات خودکار را زمانی که اندازهگیریها از تحملهای مشخص شده دور میشوند، فراهم میکند.