How Die Cutting Machines Revolutionize Packaging and Design

Die cutting machines have become a cornerstone of modern packaging and design, transforming how products are presented, protected, and perceived. These specialized tools cut, shape, and emboss materials with precision, enabling complex designs that were once impossible with manual or basic machinery. From sleek gift boxes to interactive product packaging, die cutting machines empower designers to push boundaries, while helping manufacturers meet demand for speed, consistency, and creativity. Let’s explore how die cutting machines are revolutionizing packaging and design across industries.

Precision and Consistency: Beyond Manual Cutting

Traditional packaging and design relied on manual cutting or basic tools, which often resulted in uneven edges, inconsistent shapes, and wasted materials. Die cutting machines change this by using sharp, custom-made dies (metal blades or molds) to cut materials with millimeter-perfect accuracy. Whether cutting a simple square or an intricate lace pattern, die cutting machines produce identical results every time—even across thousands of units.

This precision is game-changing for packaging. For example, a cosmetic brand needing 10,000 identical box inserts can trust die cutting machines to ensure each insert fits perfectly, avoiding gaps or misalignments that harm the product’s premium feel. In design, this consistency means logos, windows, or cut-outs on packaging look sharp and professional, enhancing brand credibility.

Die cutting machines also reduce material waste. By following exact patterns, they minimize leftover scraps, making production more efficient and eco-friendly—an important factor for brands prioritizing sustainability.

Enabling Complex and Creative Designs

Before die cutting machines, packaging and design were limited by what could be cut by hand or simple tools. Intricate shapes, pop-up elements, or layered structures were too time-consuming or costly to produce. Die cutting machines remove these barriers, letting designers explore bold, innovative concepts.

- Intricate cut-outs: Die cutting machines can create detailed patterns—like lace-like borders on gift boxes or star-shaped windows on candy packaging—that add visual interest without compromising structural strength.

- 3D and interactive elements: Pop-up cards, foldable product stands, or packaging that transforms into a display (e.g., a cereal box that becomes a toy) are made possible by die cutting machines. These designs engage customers, making products more memorable.

- Embossing and debossing: Many die cutting machines combine cutting with embossing (raising designs) or debossing (recessing designs), adding texture to packaging. A luxury chocolate box, for example, might use die cutting to emboss a logo, creating a tactile experience that feels premium.

These capabilities let brands stand out in crowded markets. A snack brand using die cutting to create a packaging shape that mimics its product (e.g., a chip bag cut like a potato) is more likely to catch shoppers’ eyes than a generic rectangle.

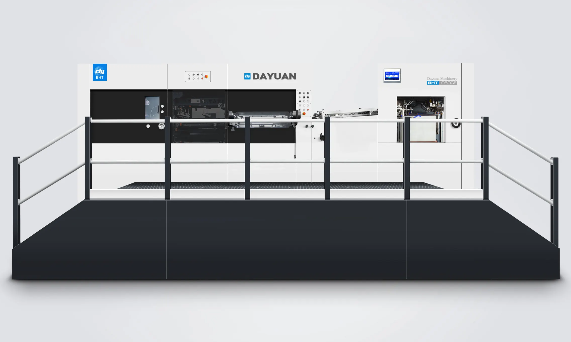

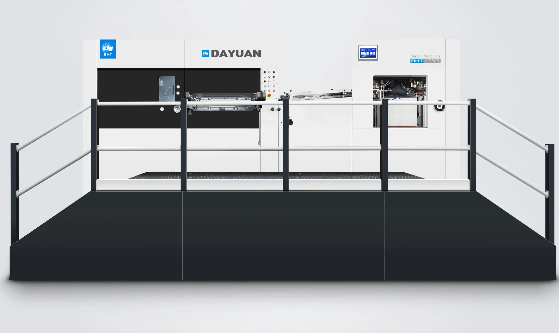

Speed and Scalability for Mass Production

In packaging, speed and scalability are critical—especially for large brands or seasonal products (e.g., holiday gift sets). Die cutting machines excel here, handling high volumes of materials quickly without sacrificing quality.

Manual cutting might produce 100 simple shapes per hour; automated die cutting machines can produce thousands in the same time. This efficiency lowers production costs and shortens lead times, letting brands respond faster to market demands. For example, a beverage company launching a limited-edition bottle label can use die cutting machines to produce 50,000 custom-shaped labels in days, not weeks.

Die cutting machines also adapt to different production scales. Small businesses can use tabletop die cutting machines for small batches (e.g., 500 wedding invitations), while large manufacturers rely on industrial models for mass production. This flexibility makes die cutting machines accessible to creators at every level.

Versatility Across Materials

Packaging and design use a wide range of materials—paper, cardboard, plastic, fabric, leather, and even thin metal. Die cutting machines handle almost all of them, expanding the possibilities for innovation.

- Paper and cardboard: The most common materials for packaging, easily cut into boxes, inserts, or folding cartons.

- Plastic: Used for blister packs (e.g., toy or electronics packaging) or flexible packaging (e.g., snack bags), die cutting machines create clean edges that seal properly.

- Fabric and leather: In luxury packaging (e.g., high-end perfume boxes with fabric accents) or branded accessories, die cutting machines cut these materials without fraying.

- Foam and rubber: Used for protective packaging (e.g., electronics inserts), die cutting machines shape these materials to cushion products during shipping.

This versatility lets designers mix materials for unique effects. A skincare brand might use die cutting machines to combine cardboard (for structure) and fabric (for a soft touch), creating packaging that’s both functional and luxurious.

Cost-Effectiveness in the Long Run

While die cutting machines require an initial investment—especially industrial models—they save money over time. Manual cutting demands labor, and errors (like uneven shapes) lead to wasted materials and rework. Die cutting machines reduce these costs by:

- Lowering labor needs: Once set up, automated die cutting machines run with minimal supervision, reducing the need for manual workers.

- Minimizing waste: Precise cuts mean less scrap material, lowering material costs.

- Reducing rework: Consistent results mean fewer defective products, saving time and money on fixes.

For small businesses, affordable tabletop die cutting machines (starting at a few hundred dollars) offer these benefits on a smaller scale, making professional-quality design accessible without breaking the bank.

Supporting Sustainable Packaging Trends

As consumers and brands prioritize sustainability, die cutting machines play a key role in creating eco-friendly packaging. They enable designs that use less material (e.g., slimmer boxes with precise fits) or incorporate recycled materials (which can be tricky to cut manually).

Die cutting machines also support “right-sized” packaging—avoiding oversized boxes that waste space and require extra filler. For example, a electronics brand using die cutting machines to create custom foam inserts can ship products in smaller boxes, reducing carbon emissions from transportation.

Additionally, die cutting machines work with biodegradable materials (e.g., plant-based plastics or molded fiber) that are often delicate. Their precision ensures these materials are cut without tearing, making sustainable packaging feasible for mass production.

Real-World Examples of Innovation

Die cutting machines have enabled iconic packaging and design moments across industries:

- Food and beverage: A cereal brand uses die cutting machines to create boxes with built-in pour spouts and resealable flaps, combining functionality with kid-friendly shapes.

- Beauty and cosmetics: A lipstick brand uses die cutting to emboss its logo on a magnetic closure box, adding a premium touch that justifies higher prices.

- Retail and gifting: Luxury brands use die cutting machines to create nested boxes (boxes inside boxes) with intricate cut-outs, turning unboxing into an experience that customers share on social media.

- Promotional products: A company uses die cutting machines to shape branded mouse pads into its logo, making giveaways more memorable.

FAQ

What materials can die cutting machines cut?

Die cutting machines handle paper, cardboard, plastic, fabric, leather, foam, rubber, and thin metal. The type of machine (manual, semi-automatic, industrial) determines which materials it can manage—industrial models handle thicker or tougher materials.

How are dies made for die cutting machines?

Dies are custom-made metal blades (usually steel) shaped into the desired design. They’re created using computer-aided design (CAD) software, ensuring precision, and then mounted onto the die cutting machine.

Are die cutting machines only for large businesses?

No. Small tabletop die cutting machines are affordable and easy to use, making them ideal for small businesses, crafters, or designers creating small batches (e.g., wedding invitations, custom labels).

Can die cutting machines create 3D designs?

Yes. By combining cutting with scoring (creating fold lines), die cutting machines make 3D structures like pop-up cards, boxes, or display stands. Some machines also emboss or deboss to add depth.

How long does it take to set up a die cutting machine?

Setup time depends on the design complexity. Simple dies (e.g., squares) take 10–15 minutes, while intricate designs with multiple cuts or embossing may take 30–60 minutes. Once set up, production runs quickly.

Do die cutting machines require maintenance?

Yes. Regular cleaning (to remove material scraps) and blade sharpening (to keep cuts precise) are needed. Industrial machines may also need periodic checks of moving parts to ensure smooth operation.

Are die cutting machines better than laser cutters?

They serve different needs. Die cutting machines are faster for mass production and better for thick materials. Laser cutters are better for ultra-fine details but are slower and more expensive for large batches.

Table of Contents

- How Die Cutting Machines Revolutionize Packaging and Design

- Precision and Consistency: Beyond Manual Cutting

- Enabling Complex and Creative Designs

- Speed and Scalability for Mass Production

- Versatility Across Materials

- Cost-Effectiveness in the Long Run

- Supporting Sustainable Packaging Trends

- Real-World Examples of Innovation

-

FAQ

- What materials can die cutting machines cut?

- How are dies made for die cutting machines?

- Are die cutting machines only for large businesses?

- Can die cutting machines create 3D designs?

- How long does it take to set up a die cutting machine?

- Do die cutting machines require maintenance?

- Are die cutting machines better than laser cutters?