How Automatic Creasing Machines Improve Packaging Production

In the fast-paced world of packaging production, efficiency, accuracy, and consistency are critical. Businesses must deliver high-quality packaging that not only protects the product but also represents the brand in a professional and visually appealing way. Creasing is one of the most important processes in packaging manufacturing, ensuring that folds are precise and the material retains its integrity during assembly and use.

While manual methods and simpler machines have served the industry for decades, the rise of Automatic Creasing Machines has transformed production capabilities. By automating the creasing process, manufacturers can significantly increase output, reduce waste, improve quality, and maintain better cost efficiency.

This article explores how Automatic Creasing Machines enhance packaging production, from their operational benefits to their role in modern manufacturing trends.

Understanding Automatic Creasing Machines

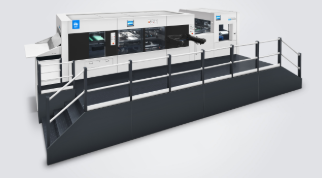

Automatic Creasing Machines are advanced equipment designed to create fold lines on paperboard, cardboard, corrugated materials, or other packaging substrates with speed and precision. Unlike manual or semi-automatic models, these machines handle feeding, positioning, and creasing automatically, often using programmable settings to produce multiple crease lines in a single pass.

These machines are widely used in industries such as folding carton manufacturing, corrugated box production, luxury packaging, and bookbinding. In packaging lines, creasing is typically followed by folding, gluing, and assembly, so the accuracy of the crease directly affects downstream processes.

The Role of Creasing in Packaging

Creasing is different from simply folding material. When paperboard or cardboard is folded without a crease, the surface fibers can crack, especially if the material is coated or laminated. This not only affects appearance but also weakens the fold.

A crease creates a controlled line of deformation, allowing the material to bend without surface damage. For packaging, this ensures:

-

Structural Integrity: Folds hold their shape without springing back.

-

Visual Appeal: No cracks or deformations in printed graphics.

-

Assembly Efficiency: Boxes and packages fold quickly and uniformly.

Automatic Creasing Machines ensure that these benefits are achieved consistently at industrial speeds.

Key Advantages of Automatic Creasing Machines in Packaging Production

1. Increased Production Speed

One of the most immediate advantages is the dramatic improvement in speed. Automatic Creasing Machines can process hundreds or even thousands of sheets per hour. This allows packaging manufacturers to meet tight deadlines, fulfill large orders, and scale production without adding more manual labor.

2. Consistent Quality

Automation eliminates variations caused by human error or fatigue. Each sheet is fed and positioned precisely, ensuring that crease depth, alignment, and pressure remain uniform throughout the run. Consistency is critical in packaging, where mismatched folds can cause assembly issues or make products look unprofessional.

3. Labor Efficiency

With an automatic system, a single operator can oversee high-volume production. This reduces the labor needed per unit of output and allows skilled staff to focus on higher-value tasks such as quality control, machine setup, or maintenance rather than repetitive manual work.

4. Multi-Function Capabilities

Many modern Automatic Creasing Machines offer more than just creasing. They can integrate functions such as perforating, folding, or scoring in the same pass. For packaging manufacturers, this means fewer machines, reduced material handling, and faster overall production cycles.

5. Adaptability to Different Materials and Designs

Automatic Creasing Machines can handle a wide range of substrates, from thin paperboard to heavy corrugated sheets. With adjustable pressure, interchangeable creasing tools, and programmable setups, they adapt quickly to different packaging designs — from small product cartons to large shipping boxes.

6. Waste Reduction

Poorly creased packaging often needs to be discarded, increasing costs and wasting material. Automated precision reduces errors and ensures that more units pass quality inspection on the first attempt.

7. Better Integration with Production Lines

Automatic Creasing Machines can be integrated into larger automated packaging lines. This seamless connection allows materials to flow from printing to creasing to folding without manual intervention, boosting overall throughput and efficiency.

Cost Benefits in the Packaging Industry

While Automatic Creasing Machines require a higher initial investment compared to manual models, the cost savings and productivity gains often lead to a quick return on investment. Savings come from:

-

Reduced labor costs.

-

Lower material waste.

-

Faster turnaround times, enabling more jobs per shift.

-

Increased capacity without additional floor space or staff.

For medium to large packaging operations, these machines often pay for themselves within one to three years, depending on production volume.

Automatic Creasing Machines and Packaging Quality

High-quality packaging is not only functional but also part of the brand’s presentation. Customers notice when boxes close properly, edges align, and graphics are undamaged.

Automatic Creasing Machines contribute to this by:

-

Applying the right amount of pressure for each material type.

-

Ensuring all creases are in the exact position.

-

Maintaining uniformity across thousands of units.

This level of precision is especially important for luxury packaging, where even minor defects can reduce perceived value.

Streamlining Custom Packaging Orders

Today’s market demands flexibility. Brands want packaging that stands out — often with unique sizes, shapes, and folds. Automatic Creasing Machines meet this demand with programmable settings that allow operators to store and recall multiple job configurations.

Changing from one job to another can be done quickly, reducing downtime and making short-run custom orders more viable without sacrificing profitability.

Maintenance and Longevity

Like all industrial equipment, Automatic Creasing Machines require regular maintenance to stay in peak condition. Preventive maintenance includes cleaning debris from creasing tools, lubricating moving parts, checking alignment, and replacing worn components.

Many newer machines include diagnostics that alert operators when maintenance is due, helping avoid unexpected breakdowns that could halt production.

With proper care, these machines can last many years, making them a long-term investment in production capacity.

Safety Considerations

Automatic Creasing Machines, despite their speed and power, are designed with operator safety in mind. Common features include:

-

Safety guards and interlocks.

-

Emergency stop buttons.

-

Sensors that prevent operation if doors or guards are open.

Proper operator training is still essential to ensure safe operation and to maximize machine efficiency.

Environmental Impact and Sustainability

Sustainability is a growing concern in packaging production. Automatic Creasing Machines help in several ways:

-

Reduced Waste: Precision cutting minimizes rejected materials.

-

Energy Efficiency: Newer models are designed with energy-saving motors and standby modes.

-

Material Versatility: Ability to work with recyclable and eco-friendly substrates.

By enabling precise creasing on sustainable materials, these machines support eco-friendly packaging initiatives without compromising quality.

Future Trends for Automatic Creasing Machines in Packaging

The packaging industry is evolving, and Automatic Creasing Machines are keeping pace with new technologies. Key trends include:

-

Smart Automation: Integration with AI to adjust settings in real time based on material behavior.

-

Industry 4.0 Connectivity: Machines connected to a central system for monitoring, scheduling, and predictive maintenance.

-

Hybrid Systems: Combining creasing with laser cutting or digital embellishment for advanced customization.

-

Compact High-Output Models: Smaller footprints but high production rates for space-limited facilities.

These trends suggest that the role of Automatic Creasing Machines will only grow in the coming years, making them a must-have for competitive packaging manufacturers.

Conclusion

Automatic Creasing Machines have revolutionized packaging production by delivering speed, accuracy, and flexibility that manual and semi-automatic systems cannot match. They allow manufacturers to produce large volumes of perfectly creased packaging quickly and consistently, while reducing labor costs, minimizing waste, and meeting increasingly tight deadlines.

For businesses focused on high-volume packaging, the investment in Automatic Creasing Machines quickly pays off, enabling them to meet market demands with ease and efficiency. Even for smaller operations, the ability to handle custom jobs quickly and maintain consistent quality makes automation an attractive option.

As consumer expectations and industry standards continue to rise, packaging manufacturers that adopt Automatic Creasing Machines will be better positioned to compete, innovate, and grow sustainably. By integrating these machines into modern production lines, companies can achieve a balance between efficiency, quality, and flexibility — key factors in the ever-evolving packaging industry.

FAQ

How fast can Automatic Creasing Machines operate?

High-end models can process thousands of sheets per hour, depending on material type and complexity.

Are they suitable for small packaging runs?

Yes. Programmable settings allow quick changeovers, making them efficient even for short runs.

Do they require a lot of training?

Operators should receive training on setup, operation, and safety, but modern interfaces make learning straightforward.

Can they work with eco-friendly materials?

Absolutely. They can crease recycled and recyclable substrates as well as specialty eco-friendly boards.

What is the lifespan of an Automatic Creasing Machine?

With proper maintenance, these machines can operate reliably for many years, often over a decade in industrial use.

Table of Contents

- How Automatic Creasing Machines Improve Packaging Production

- Understanding Automatic Creasing Machines

- The Role of Creasing in Packaging

- Key Advantages of Automatic Creasing Machines in Packaging Production

- Cost Benefits in the Packaging Industry

- Automatic Creasing Machines and Packaging Quality

- Streamlining Custom Packaging Orders

- Maintenance and Longevity

- Safety Considerations

- Environmental Impact and Sustainability

- Future Trends for Automatic Creasing Machines in Packaging

- Conclusion

- FAQ