A Comprehensive Guide to Choosing the Perfect Die Cutting Machine

Whether you're a small business owner, a crafter, or part of a large manufacturing team, selecting the right die cutting machine can boost efficiency, improve quality, and save time. For businesses focused on paper and paperboard products—like packaging, stationery, and specialized prints—choosing the perfect machine requires careful consideration of your specific needs.

This guide breaks down the key factors to help you find the ideal die cutting machine capable of handling everything from delicate art paper to robust Corrugated board.

Define Your Purpose and Projects

The first step in choosing a die cutting machine is to clarify what types of paper products you'll use it for. Die cutting machines vary widely in capability, so your specific projects will dictate the best fit:

-

Crafts and Custom Stationery: If you're making intricate invitations from cultural paper or custom labels from glossy photo paper, a small, manual or desktop digital die cutter is perfect for low-volume, detailed work.

-

Packaging Production (Medium Volume): For creating folding cartons from Cardboard, specialized boxes from Gray background white board paper, or Packaging paper for cigarettes and alcohol, look for a semi-automatic machine. These offer larger cutting beds and sufficient power to handle thicker boards consistently.

-

Industrial Manufacturing (High Volume): If you need thousands of cuts daily for materials like Newsprint or large sheets of Printing Paper, an industrial automated machine is necessary. These prioritize speed, feeding efficiency, and minimal downtime.

Knowing your primary use ensures you don't overspend on features you don't need or end up with a machine that's too weak for your core paper projects.

Consider the Paper Materials You'll Cut

Die cutting machines must be specifically selected for the thickness and density of the paper-based materials you intend to process.

| Material Type | Typical Machine Requirement |

| Thin Paper (e.g., Newsprint, Offset paper) | Manual or Semi-automatic; requires low, adjustable pressure to prevent crushing or tearing. |

| Coated/Mid-Weight Board (e.g., Copperplate Paper, two-sided offset paper) | Semi-automatic or Automatic; needs consistent, even pressure for clean scoring and cutting. |

| Thick Board (e.g., Cardboard, Corrugated board, Gray background white board paper) | Flatbed machine with significant pneumatic or hydraulic pressure to cut cleanly through multiple layers. |

| Specialty Papers (e.g., Aluminum foil paper, laser paper) | Requires high precision registration and the ability to handle potentially brittle or delicate coatings without cracking. |

| Functional Papers (e.g., Burger paper, Greaseproof paper) | Requires clean cutting and may need specific die materials to prevent sticky residue buildup. |

Always check the machine's pressure capacity to ensure it can cut through your thickest Corrugated board while still being gentle enough for your thinnest cultural paper.

Evaluate Size and Cutting Capacity

The right size die cutting machine depends on the size of your raw material sheets and your available workspace.

-

Cutting Bed Size: This is the maximum area the machine can process in one pass. For small custom items, a 12x18 inch bed is adequate. For large format packaging or efficient nesting of multiple small parts from Printing Paper, choose a machine with a bed of 30 inches or more.

-

Workspace Availability: Tabletop die cutting machines (about

feet wide) fit easily in small workshops. Industrial flatbed or rotary models can take up significant floor space (e.g.,

square feet) and require dedicated installation.

A larger cutting bed allows you to cut bigger materials or nest multiple small items onto one sheet (like multiple box blanks from a sheet of Cardboard), dramatically saving time and reducing material waste.

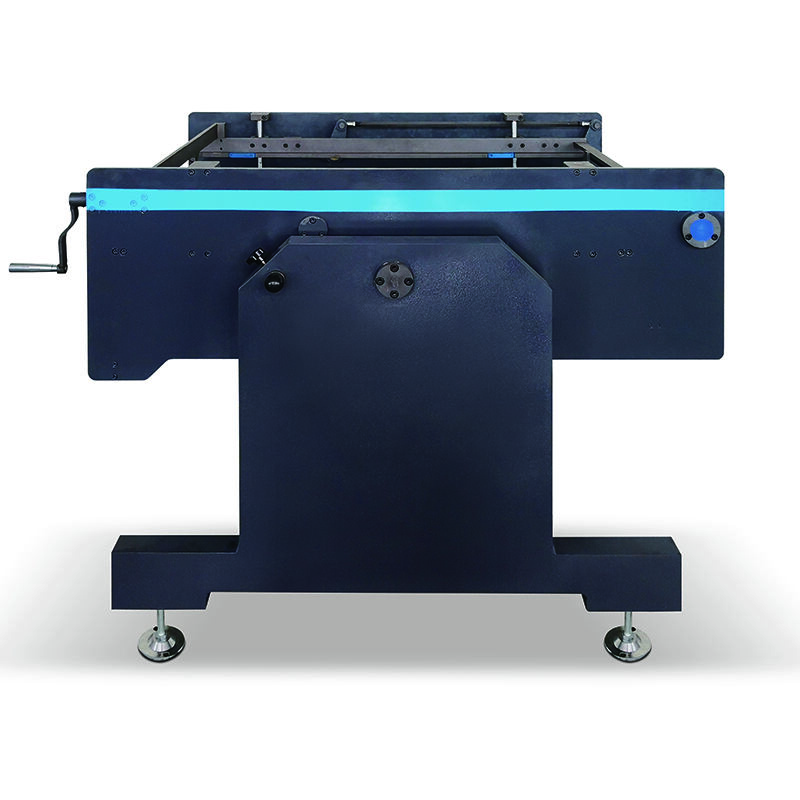

Choose Between Manual, Semi-Automatic, or Automatic System

| Type | Best For | Production Rate | Key Features |

| Manual | Hobbyists, low-volume custom work (e.g., |

Very slow (a few cuts per minute). | Low cost, portable, requires physical effort. |

| Semi-Automatic | Small-to-medium business packaging runs (e.g., |

Moderate (10-50 cuts per minute). | Consistent electric/pneumatic pressure, greater accuracy, moderate price. |

| Automatic | Industrial manufacturers (e.g., |

Fast (100+ cuts per minute). | Conveyor feed, computerized controls, high precision, high initial investment. |

For most businesses focusing on packaging and high-end stationery, a semi-automatic machine offers the best balance of efficiency, precision, and cost.

Check Key Features for Precision and Ease of Use

Certain features are essential for quality paper cutting and long-term efficiency:

-

Adjustable Pressure: Absolutely necessary to switch cleanly between delicate papers (Newsprint) and thick boards (Corrugated board).

-

Precise Registration System: For cutting pre-printed materials (like Copperplate Paper or Aluminum foil paper), the machine must have optical sensors or advanced guides to ensure the die lines up perfectly with the printed image.

-

Interchangeable Dies: Ensure the machine is compatible with widely available or custom dies (steel rule or chemical-etched) to handle different shapes and designs.

-

Digital Controls: Found on higher-end models, these allow operators to quickly save and recall pressure and speed settings for specific jobs (e.g., "Setting 1: Cardboard Box," "Setting 2: Offset paper Label").

Frequently Asked Questions

What size die cutting machine do I need for paper packaging?

For small folding cartons (e.g., for candles or cosmetics) a 12×18 inch to 18×24 inch bed is usually sufficient. For large shipping boxes made of Corrugated board or for maximum efficiency via nesting, look for a machine with a 30+ inch cutting area.

How is a die cutting machine different from a digital cutting machine (plotter)?

A die cutting machine uses a physical steel rule die and high pressure to cut all parts simultaneously in one powerful press, making it faster and better for thick Cardboard and high volumes. A digital plotter uses a moving blade and cuts outlines sequentially, offering lower volume flexibility but struggling with very thick paperboard.

How often do the steel rule dies need replacement?

The lifespan of a steel rule die depends on the material cut. When cutting paper and paperboard, a quality die can last for several hundred thousand impressions before the blade edges dull and require replacement or sharpening.

Can I use the same die to cut both thin and thick paper?

Yes, you can use the same die, but you must adjust the machine's pressure and cutting plate height between jobs. Cutting thick Cardboard requires much higher pressure than cutting thin wood-free printed paper.

Table of Contents

- A Comprehensive Guide to Choosing the Perfect Die Cutting Machine

- Define Your Purpose and Projects

- Consider the Paper Materials You'll Cut

- Evaluate Size and Cutting Capacity

- Choose Between Manual, Semi-Automatic, or Automatic System

- Check Key Features for Precision and Ease of Use

- Frequently Asked Questions