Üstün Malzeme Taşıma Kapasitesi

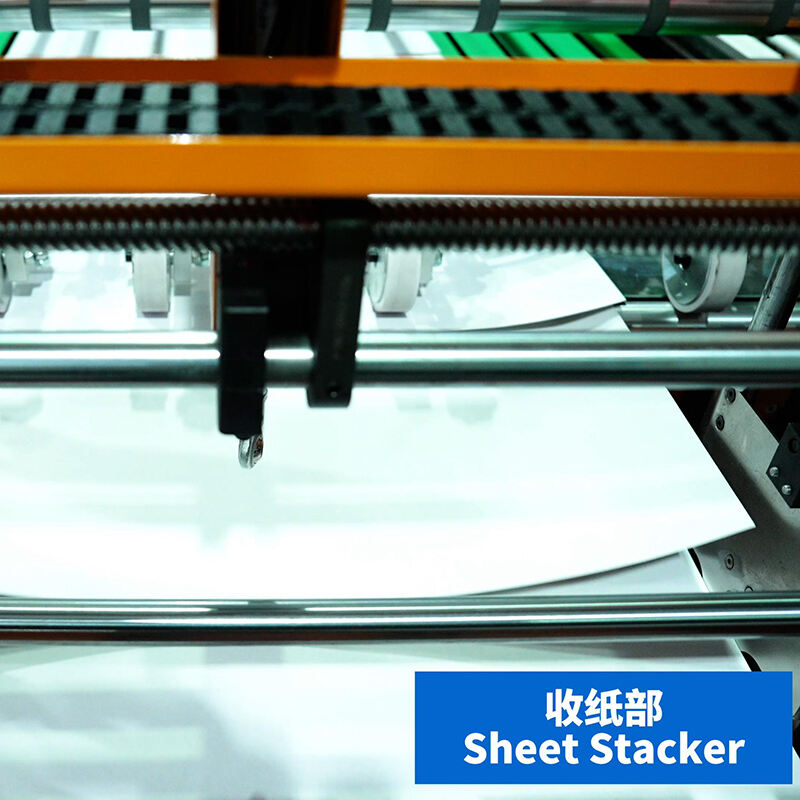

Makinenin gelişmiş malzeme işleme sistemi, rulo-kağıt dönüşüm teknolojisi açısından önemli bir ilerleme temsil eder. Sistem, kesim süreci boyunca optimal malzeme gerilimini koruyan otomatik gerilim kontrolüne sahip hassas şekilde tasarlanmış ruloları içerir. Bu sofistike gerilim yönetimi, malzeme bozulmasını engelleyerek, malzeme türü veya kalınlığı ne olursa olsun doğru kesimi sağlar. Besleme sistemi, malzemeyi tamamen ortada tutarak çarpık kesimleri ortadan kaldırır ve atıkları azaltır olan otomatik kenar hizalama ve web rehberlemesi teknolojisi içerir. Feed yolu boyunca bulunan birden fazla sensör, malzeme hareketini izler ve optimal performansı sağlamak için otomatik olarak parametreleri ayarlar. Sistem, hassas malzemeleri hasar vermeyecek şekilde işlerken yine de yüksek üretim hızını korur, bu da onu hem standart hem de özel uygulamalar için ideal hale getirir.