- ဆီလျော်သော

- နည်းပညာ အတိုင်းအတာများ

- ပတ်သက်သော ပণုံများ

- မေးလေ့ရှိသောမေးခွန်းများ

ထုတ်ကုန်ဖော်ပြချက်

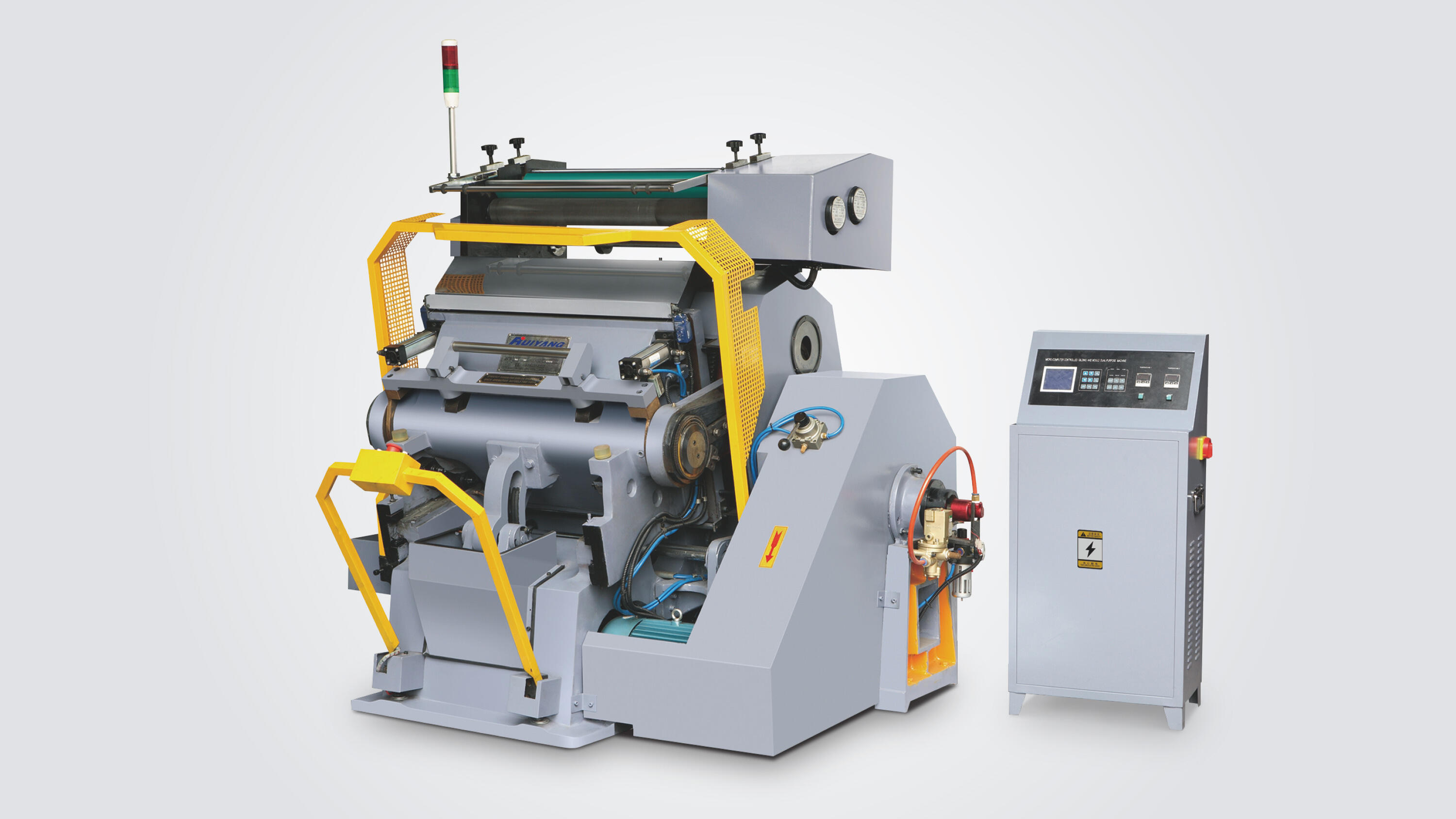

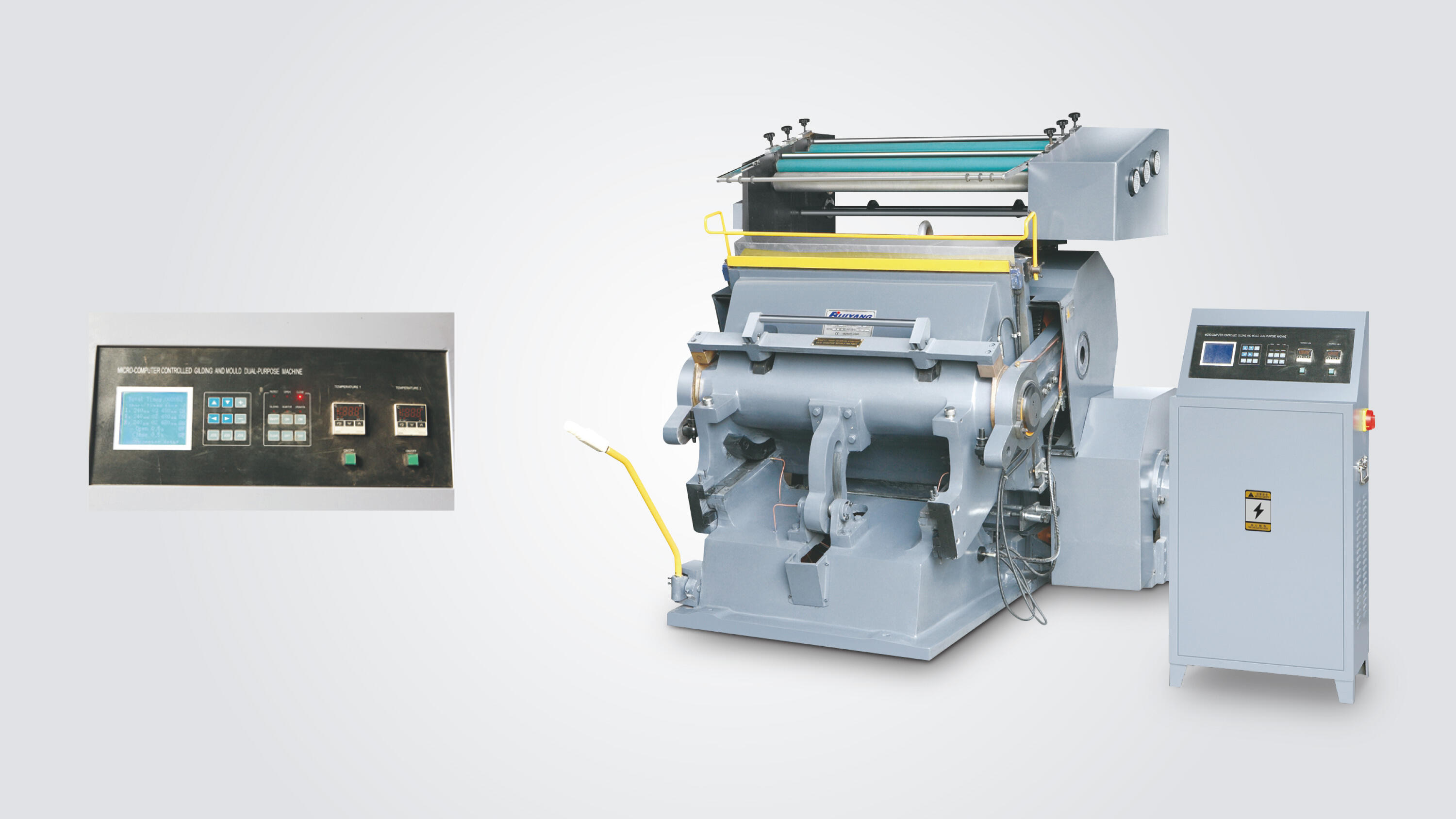

TYMB စီးရီးလက်ဖြင့်ပူးတွဲထုတ်လုပ်သော အပူနှိပ်ခြင်းနှင့် ဒိုင်းဖြတ်ခြင်းစက်မှာ နာရီကြေးပစ္စည်းများ၏တိကျမှုနှင့် သာလွန်သောအကျိုးသက်ရောက်မှုတို့ဖြင့် ထုတ်လုပ်ထားသည့် နောက်ဆုံးပေါ်စက်ရုံထုတ်ကုန်ဖြစ်ပါသည်။ TYMB စီးရီးမော်ဒယ် ရွှေနှိပ်ခြင်း၊ ဖြတ်ခြင်းနှင့် အမှတ်အသားထိုးနှိပ်ပေးသောစက်များကို အမျိုးမျိုးသောအရောင်ဓာတုအလူမီနီယမ်ပါဝင်သော အလွှာများကို ရွှေနှိပ်ထုတ်ဝေရန်၊ အောက်ပြားပေါ်ပြားပုံစံဖြင့် ပုံများ၊ ကုန်အမှတ်တံဆိပ်များ၊ ကြော်ငြာများ၊ နမူနာအိတ်၊ စာအုပ်မျက်နှာဖုံးများနှင့် နှစ်သစ်ကူးကတ်များကို အလှဆင်နိုင်ရန်အတွက် အသုံးပြုသည်။ စက္ကူ၊ ဂျုံထုပ်ပါအိတ်၊ ပလပ်စတစ်၊ အရေပြားနှင့် ပတ်သက်သောပစ္စည်းများကို အသုံးပြုသော စက်များအတွက် စာနှိပ်ခြင်း၊ ပက်ကေ့ခ်ကုန်ပစ္စည်းများ၊ အလှဆင်ခြင်းနှင့် ပလပ်စတစ်စက်မှုလုပ်ငန်းများအတွက် အကောင်းဆုံးကိရိယာဖြစ်ပါသည်။

အဓိက အချက်များ

မြင့်မားတဲ့ ပို့ဆောင်ချက်ရှိ အရည်အချင်းကို အသုံးပြုတယ်

လှိုင်းလေးခုရဲ့ မျဉ်းကျော်ဖြစ်သော ဖွဲ့စည်းပုံကို အသုံးပြုပြီး လုပ်ဆောင်မှုက မြောက်မားပြီး၊ ကြီးမားသော ဖြတ်ခြင်း၊ အသံကို နည်းပါတယ်။

လေကို အသုံးပြုပြီး ဖြတ်တွက်ချက်ရှိတယ်။ လွယ်ကူသော၊ သေချာတဲ့၊ အာရုံစိုက်ပြီး သေချာတယ်

လောင်းချိုးကို အင်တန်း ၄၅ ဖြင့် အသုံးပြုတယ်။ အကြီးမားတဲ့ အားကို အသုံးပြုတယ်

အမြင့်မှာ သံကို ဖြတ်တွက်ချက်ရှိတယ်။ အင်္ဂါထဲမှာ ဖြတ်တွက်ချက်ရှိတယ်

မြင့်မားတဲ့ ဖြတ်တွက်ချက်ရှိတယ်။ အားလုံးကို ဖြည့်စွက်ထားတယ်

IEC standard အရောင်းအဝယ်အတိုင်း ဒီဇိုင်းထုတ်ထားတယ်

တစ်ခုခုလုပ်တဲ့ ဖြတ်တွက်ချက်၊ ဆက်လက်လုပ်တဲ့ ဖြတ်တွက်ချက်၊ အချိန်ကို နှိုင်းယှဉ်တဲ့ ဖြတ်တွက်ချက်တွေရှိတယ်။ အကြီးမားတဲ့ အားလုံးကို ပြင်ဆင်နိုင်တယ်

အောက်ပါ စျေးနှုန်းများသည် ရှိရင်းအခြေခံဖြင့် ပြောင်းလဲခြင်း၊ ဖယ်ရှားခြင်းနှင့် ထပ်တူညီမှုများအား ပြုလုပ်နိုင်သည်။

အုပ်စုဖွဲ့ခြင်းနှင့် ရောင်းချခြင်းစနစ်။

နည်းပညာ အတိုင်းအတာများ

|

မော်ဒယ် |

အများဆုံး ပလေတင်း ပုံသားအကျယ် |

အများဆုံး ပြင်ဆင်ခြင်း ဧရိယာ |

ချောက်ခြင်းအကွာအဝေး |

အလုပ်လုပ်ဖိအား |

ဖိုင်လ်ကို ပေးထားသော အလျှော့အရှည် |

ဖိုင်လ်ကို ပေးထားသော အစုံ |

အလုပ်နှုန်း |

အဓိက မော်တာ |

စုစုပေါင်းစွမ်းအား |

အလုံးအရင်းအတိုင်းအတာ |

Total weight |

|

TYMB750 |

750×520mm |

740×510mm |

ကွန်ပျူတာနှင့် တူညီသော အတွင်းရှိ အကိုင်းကိုင်မှု |

၁၀၀T |

500mm |

2(အိမ်) |

1380အကြိမ်/နာရီ |

2.2kw |

10KW |

2150x1400x1900mm |

2500kg |