- Apžvalga

- Techniniai parametrai

- Susijusios produktai

- DUK

Produkto aprašymas

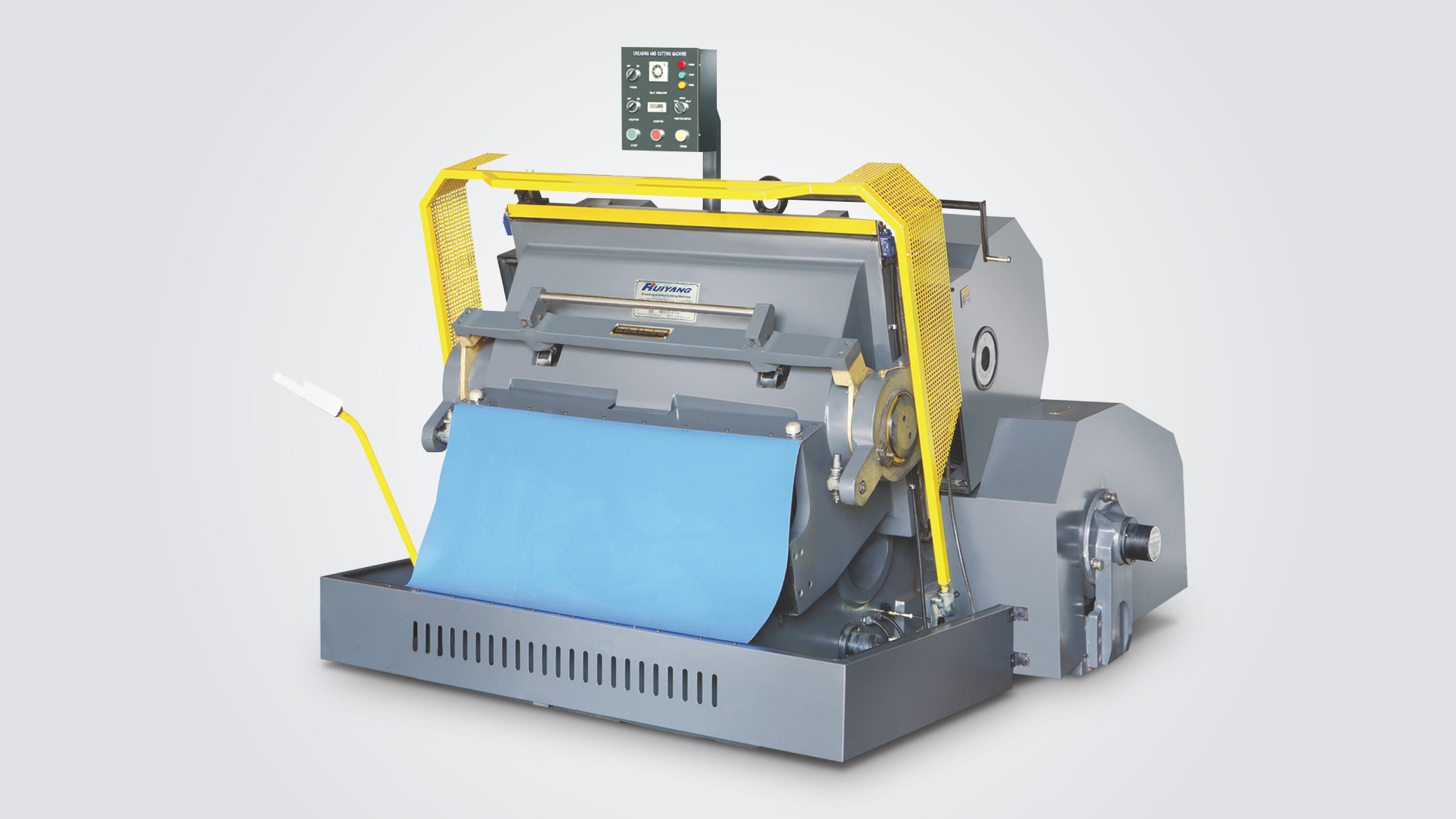

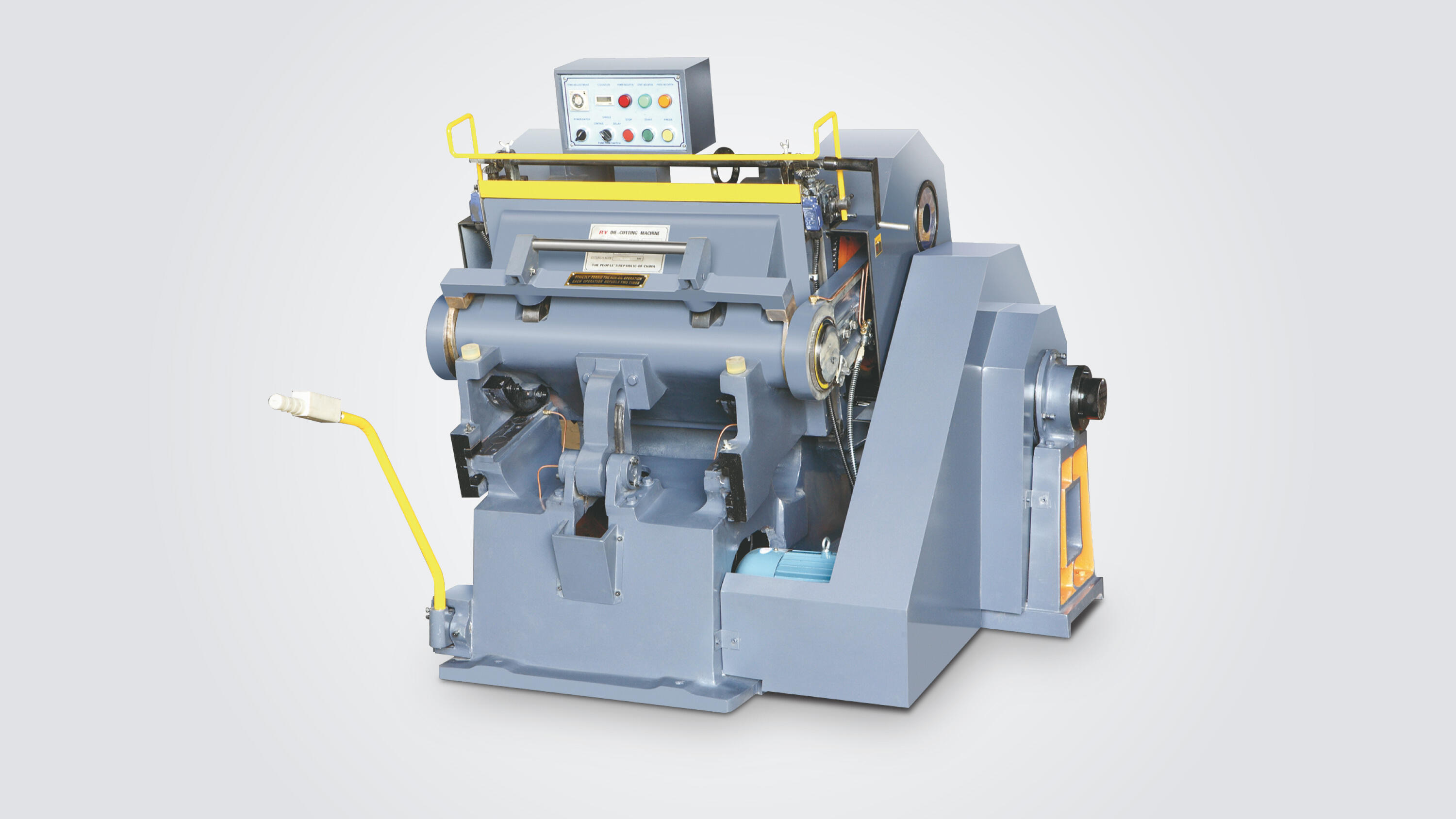

PYQ/ML-serijos rankinis lenkimo ir iškirpimo mašina yra speciali įranga visų rūšių paprastiems segtuvams, gofruotoms plokštėms, plastikiniams lakštams, odos gaminams. Ši PYQ/ML-serijos rankinė iškirpimo mašina tinka spausdinimui, pakuotei, apdailai, plastikų pramonei ir pan. Ji turi tvirtą konstrukciją, rafinuotą gamybą, puikų pjaustymą, aukštą tikslumą, lengvą naudotojo sąsają, saugumą ir patikimumą.

Pagrindinės savybės

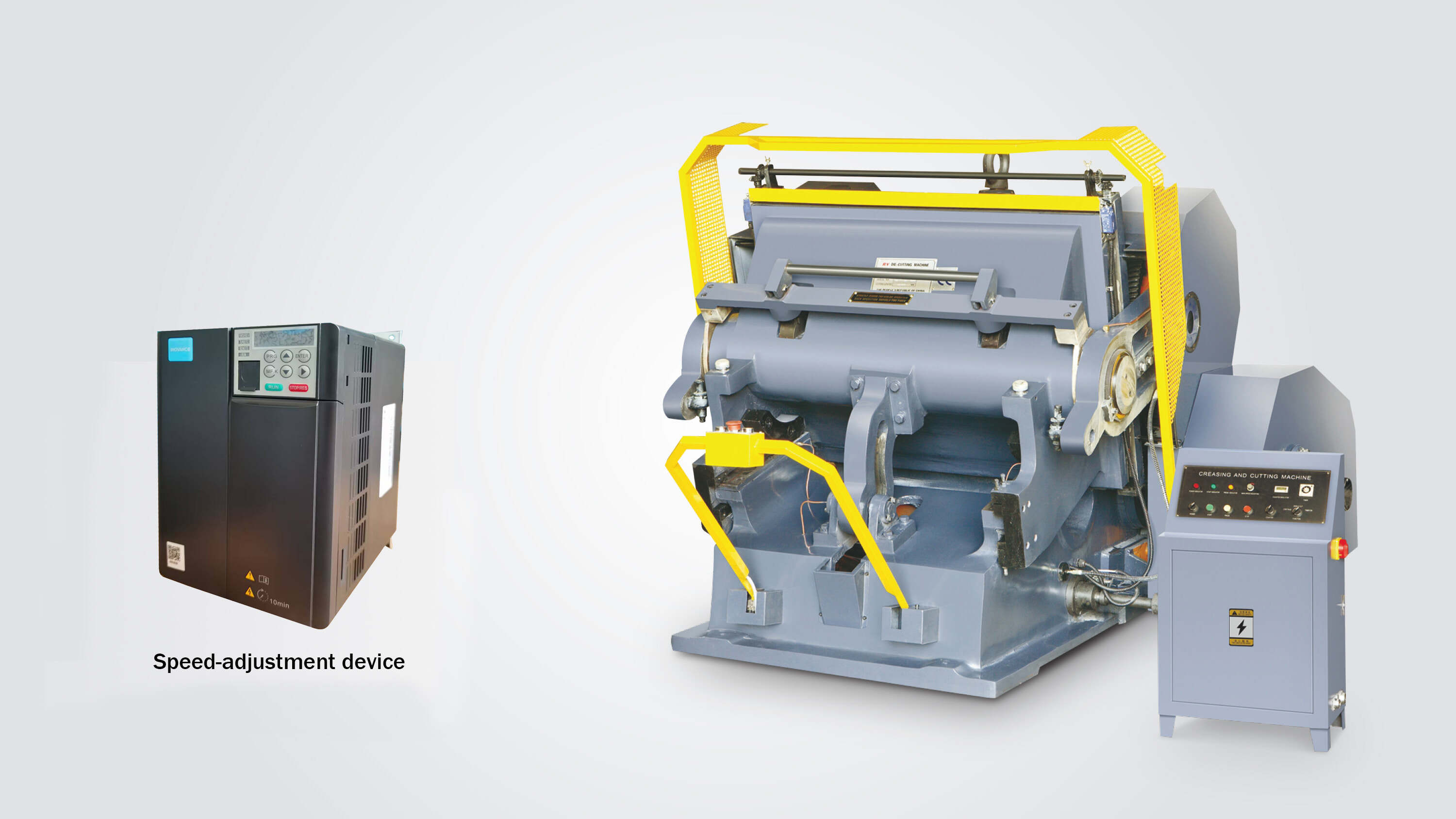

Įrenginys montuoja greičio reguliavimo įrenginį

Jis naudoja aukštos kokybės medžiagą ir aukštą įtempą leistį.

Jis naudoja keturios ašies nuožulniojo ratelio struktūrą su stabilia veikla, gera pjovimo, maža triuškimas.

Jis naudoja oro traukinį su lankstumu, patikimumu ir sauga.

Sujungiamasis stabas yra iš 45# angliavos plieno su dideliu stiprumu.

Garsas ir jo aukščio išdėstymas, rėmimo koordinates.

Jis naudoja mikrodermalaus reguliavimo ratai su aukštu tikslumu.

Elektrinis sistemą yra sukurtas pagal IEC standartą.

Jis turi tris funkcijas vienam pjovimui, sekantiniams pjovimams, laiko delsa, jo diapazonas gali būti reguliuojamas.

Saugumo apsauginis sistemą yra patikima.

Konscentruota smėliavimo sistema.

Greičio reguliavimo įrenginys

Techniniai parametrai

|

Modelis |

Vidinio rėmo dydis |

Greitis (kartų/min) |

Maks. taisyklės ilgis |

Variklio galia |

Mašinos svoris |

Pakuotės (bendrosios) matmenys |

|

PYQ401C |

750×520mm |

25 |

<15m |

2.2kw |

2000kg |

1650x1400x1500mm |

|

PYQ203C |

930×670mm |

23±3 |

<25m |

4kw |

3000kg |

1750x1900x1700mm |

|

PYQ203A |

930×670mm |

23±3 |

<30m |

5.5kw |

3500kg |

1850x1950x1700mm |

|

PYQ203AQ |

930×670mm |

23±3 |

<30m |

5.5kw |

3500kg |

1850x1950x1700mm |

|

ML1040 |

1040x720mm |

23±3 |

<28m |

4kw |

3500kg |

2000x2010x1900mm |

|

ML1100A |

1100x800mm |

22±2 |

<35m |

7,5 kW |

5000kg |

2000x2010x1900mm |

|

ML1100 |

1100x800mm |

20±2 |

<30m |

5.5kw |

4500kg |

2020x2010x1900mm |

|

ML1200 |

1200x820mm |

20±2 |

<32m |

5.5kw |

5000kg |

2020x2020x1950mm |

|

ML1300 |

1300x920mm |

15±2 |

<40m |

7,5 kW |

6000kg |

2600x2100x1950mm |

|

ML1400 |

1400x1000mm |

15±2 |

<45m |

7,5 kW |

6500kg |

2600x2100x1950mm |

|

ML1500 |

1500x1050mm |

14±2 |

<45m |

7,5 kW |

7000 kg |

2650x2100x2000mm |

|

ML1500G |

1500x1150mm |

14±2 |

<45m |

7,5 kW |

7300kg |

2650x2100x2050mm |

|

ML1600 |

1600x1250mm |

13±2 |

<50m |

11 kW |

11500kg |

2850x2250x2100mm |

|

ML1800 |

1800x1280mm |

13±2 |

<60m |

15kw |

13000kg |

3150x2250x2250mm |

|

ML1800G |

1800x1400mm |

13±2 |

<60m |

15kw |

14000kg |

3150x2250x2300mm |

|

ML2000 |

2000x1400mm |

12±2 |

<65m |

15kw |

15500kg |

3150x2250x2300mm |

|

ML2200 |

2200x1400mm |

12±2 |

<68m |

18KW |

16500kg |

3300x2250x2300mm |

|

ML2500 |

2500x1500mm |

12±2 |

<70m |

22kw |

18500kg |

3600x2250x2500mm |

|

ML2600 |

2600x1500mm |

12±2 |

<70m |

22kw |

20000kg |

3700x2250x2500mm |

|

ML2800 |

2800x1500mm |

12±2 |

<75m |

22kw |

23000 kg |

3900x2300x2800mm |

|

ML3000 |

3000x1600mm |

12±2 |

<80m |

30Kw |

35000kg |

4200x2300x3000mm |