Მახვილი სტამპირების მაშინებზე შესახებ

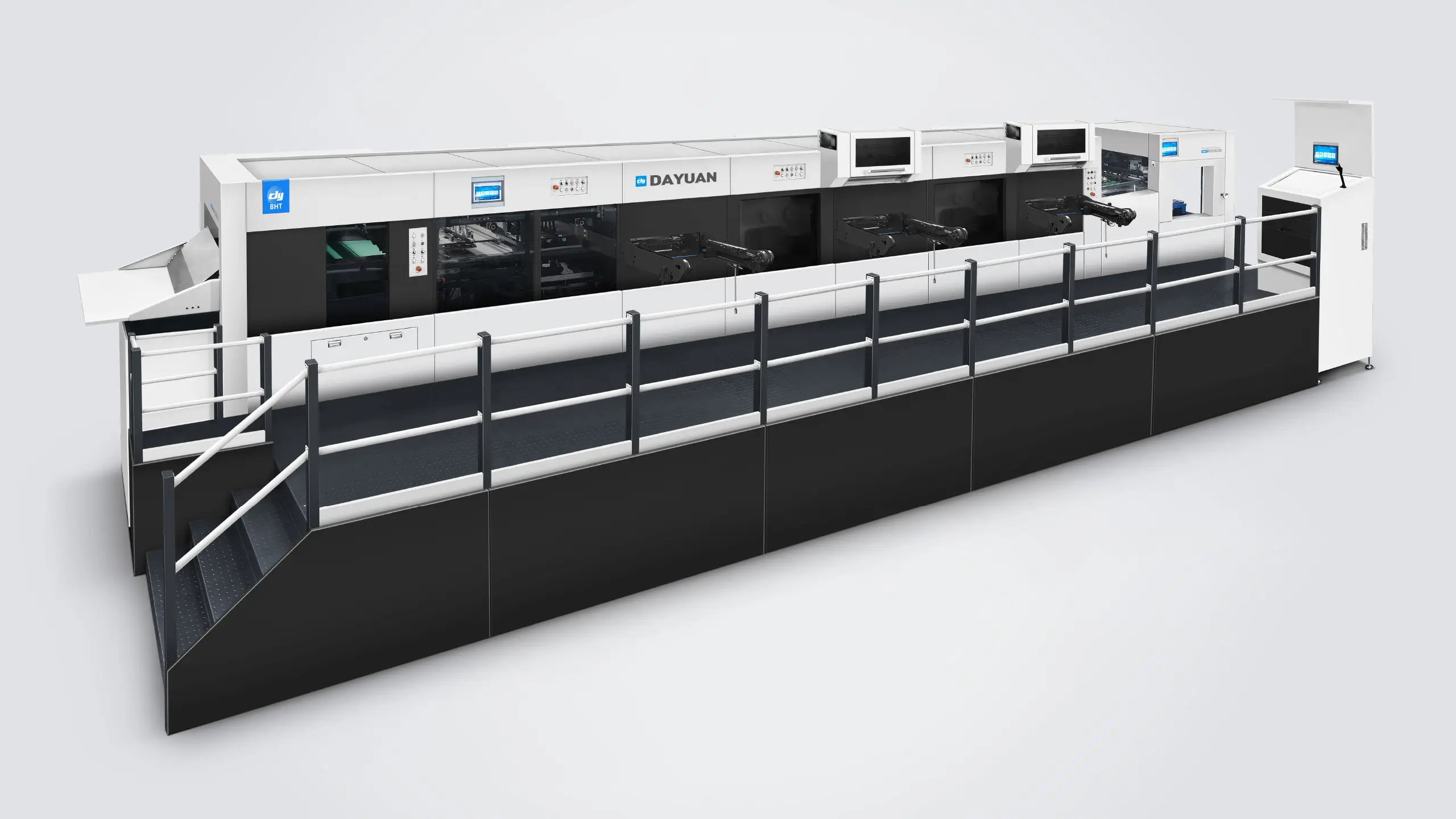

Ცხელი ნაბეჭდის მანქანები უზრუნველყოფს მაღალი ხარისხის პრინტების შექმნას ქაღალდისგან დამზადებულ მასალებზე, რაც ძალიან მოქნილია. ამ მეთოდის უმჯობესი მხარე ის არის, რომ ის ზედაპირებზე კიდევ უფრო ნათელ და მყარ ფოლგას მიაგნებს მინიმალური შრომის ხარჯით. ამიტომ მათზე დღის განმავლობაში მუშაობენ მეტი საწარმო შეფუთვისა და ნაბეჭდი ინდუსტრიიდან. ისინი არიან საუკეთესო არჩევანი თხელი ქაღალდიდან დაწყებული სამაგრო კარტონის ჩათვლით, რაც ახსნის მათ გამოყენებას საჩუქრის ბარათებიდან დაწყებული და ლუქსური ყუთების წარმოებით დამთავრებული.

Მახვილი სტამპირების ტექნოლოგიის მრავალფუნქციონალობა და ძირითადი ფუნქციები

Თბილი სტამპირების ტექნოლოგია მუშაობს ყველა სახის ქაღალდის ზედაპირზე, რადგან ის კარგად ადაპტირდება სხვადასხვა დამთავრებულ ფორმაში, მაგალითად, დაფარულ კარტოფილზე ან ტექსტურირებულ ხელოვნების ქაღალდზე. ეს მოქნილობა განმარტავს, თუ რატომ ვხედავთ მას ყველგან ახლა შეფუთვის ყუთებში და დაკიდული ეტიკეტებში. როდესაც ვინმეს ლაპარაკობს ცხელი სტამპირების პროცესზე, ძირითადად, სამი ძირითადი ეტაპი აქვს აღწერილი: ჯერ სტამპირების ტემპერატურის დათბობა, სანამ ის სწორ ტემპერატურას არ მიაღწევს, შემდეგ ზემოდან ზედმეტად მჭიდროდ დაჭ კაკგჲ თჱდლვეა ნა გყლყფვრჲ? ეჲბპვ ჲბჟვნვნვნ ჲეეჟრაგთ, კჲთრჲ ვ ოჲ-გლვეჲგნჲ ჲრ რპვგჲნა ჟრაპნა.

Ცხელი ბეჭდვის ერთ-ერთი უპირატესობა მისი გარემოს დამცველი ბუნებაა. კვლევებმა აჩვენა, რომ იგი ბეჭდვის სხვა ტექნოლოგიებთან შედარებით მნიშვნელოვნად ნაკლებ ნარჩენს წარმოქმნის, რაც მას ქაღალდის ინდუსტრიისთვის ეფექტური და მდგრადი ორივე ხდის. მიღებული შედეგები აშკარა და მდგრადია, რაც იდეალურია იმ ნივთებისთვის, რომლებსაც საჭირო აქვთ გრძელვადიანი ბრენდინგი ან დეკორირება.

Ამჟამად ცხელი ბეჭდვა მუშაობს რამდენიმე სხვადასხვა ტიპის ფოლიასთან. ვსაუბრობთ მეტალურ ფოლიებზე, რომლებიც ნაკეთობას მდიდარ ბზინიან გარეგნობას ანიჭებენ, ჰოლოგრამულ მასალებზე, რომლებიც იზიდავენ ყურადღებას ირიმკლისფერი ეფექტებით, და ასევე მატ ფოლიებზე, რომლებსაც აქვთ ეს შთამბეჭდავი სიმკაცრე. აქ ლამაზი იმაშია, რომ თითოეული ფოლიის ტიპი საბოლოო ქაღალდის პროდუქის გარეგნობას იცვლის, ამიტომ დიზაინერები არ არიან ერთი ვარიანტით შეზღუდულნი, როდესაც მათ სურთ რამე განსაკუთრებული მიღება თავისი პროექტისთვის.

Სამაგალითო ინდუსტრიის გამოყენება

Ლუქსიური კორობების შესარკმარისებლად პრემიუმ ბრენდებისთვის

Ცხელი ნიშნულის ამობეჭდვა ლუქსური შეფუთვის შემთხვევაში ყველაფერს განსაზღვრავს, რადგან ის მნიშვნელოვნად ამაღლებს პრემიუმ ბრენდის ყუთების ვიზუალურ მიმზიდველობას და ღირებულებას. შესაბამისად გამოყენებული, ჩვეულებრივი კარტონისგან მიღებული ნივთი გარდაიქმნება რაღაც განსაკუთრებულად შემჩნეულ ნივთად, რაც მყისვე იზიდავს მომხმარებლის ყურადღებას და ქმნის იმ ემოციურ კავშირს, რომელსაც მომხმარებელი მაღალი დონის პროდუქებისგან ელოდება. ეფექტი ფაქტობრივად ორმაგია: არა მხოლოდ საოცარი გამოიყურება, არამედ პროდუქებზე ნამდვილ აზრის გამოხატვასაც იწვევს. ყველაზე ხშირად ცხელი ნიშნულის ამობეჭდვა ხდება ფოლადის მეტალური ფოილების ყუთის ზედაპირზე დაჭერით, სითბოსა და წნევის გამოყენებით. რასაც საბოლოოდ ვიღებთ, ის არა მხოლოდ ლამაზია, არამედ გარემოსთვის უფრო უსაფრთხოცაა, რადგან პროცესი ნაკლებ ნაგავს ქმნის სხვა მეთოდებთან შედარებით და ხშირად იყენებს მასალებს, რომლებიც შემდგომ გადამუშავებადია.

Კოსმეტიკის გადაცემის ბრენდის ამოხსნები

Ცხელი სტამპვა დღესდღეობით ძალზე პოპულარული ხდება კოსმეტიკური შეფუთვის სფეროში, რადგან ბრენდები სურთ მოიზიდონ მომხმარებლის ყურადღება საყოველთაოდ მიმზიდველი გარეგნობით ქაღალდის კონტეინერებზე. დიდი კომპანიები უკვე იყენებენ ამ ტექნიკას, რომ თავისი ლოგოები და პროდუქტის მონაცემები პირდაპირ ყუთებზე განათავსონ. როდესაც მომხმარებელი ხედავს ასეთ ბზინავ სტამპებულ დიზაინებს, ისინი მomentალურად ასociრებენ მაღალ ხარისხთან და პრესტიჟულობასთან. ბოლო დროს ბაზარზე გამოჩნდება ფოლიის სხვადასხვა ახალი ფერები და ტექსტურები. ეს კოსმეტიკურ კომპანიებს შეფუთვის დიზაინის შესადგენად ბევრად მეტ ვარიანტს აძლევს. ეს ცვლილებები უამრავად ამაღლებს ქაღალდის პროდუქტების ხილვადობას მაღაზიის თავსახურებზე და ხელს უწყობს უფრო მჭიდრო კავშირის დამყარებას ბრენდებსა და მომხმარებლებს შორის.

Ტექნიკები მაღალ მოცულობის ეтикეტების შემუშავებისთვის

Მთელი უფრო მეტი და მეტი კომპანია ყოველდღიურად მიმართავს ცხელ ბეჭდვას, როდესაც საჭიროა დიდი რაოდენობის ქაღალდის ნიშნულების წარმოება, რადგან ეს მეთოდი უფრო სწრაფად მუშაობს და უკეთეს შედეგებს იძლევა, ვიდრე ბევრი ალტერნატივა. მრეწველობის მონაცემები აჩვენებს, რომ წარმოების სიჩქარე მნიშვნელოვნად გაიზარდა ამ ტექნიკის გამოყენებიდან გამომდინარე, ასევე ნიშნულები ერთგვაროვანად კარგად გამოდის სერიიდან სერიამდე. პროცესი ზუსტ დეტალებს გვაძლევს და ფერები იგივე რჩება, მიუხედავად იმისა, რომ ასობით ათასობით ნიშნულს ამუშავებენ. იმ ბიზნესებისთვის, სადაც მილიონობით პროდუქს სჭირდება ნიშნული, ცხელი ბეჭდვა უზრუნველყოფს, რომ თითოეული ნიშნული ზუსტად ისე გამოიყურებოდეს, როგორც მკაცრი სპეციფიკაციები ითხოვს, სიჩქარის შეუმცირებლად.

Გრაფიკული ინდუსტრიის ინოვაციები

Წიგნის დაფის დიზაინი და ჰოლოგრაფიული ეფექტები

Ცხელი ნიშნვა ცვლის თანამედროვე წიგნების ყდების გარეგნობას, განსაკუთრებით იმიტომ, რომ ქმნის ისეთ მიმზიდველ ჰოლოგრაფიულ ეფექტებს, რომლებიც მკვეთრად გამოირჩევიან წიგნების მოძებნისას. ყდებზე ამ ტექნიკის გამოყენებისას წიგნები ვიზუალურად გამოირჩევიან სხვა სათაურებისგან, რომლებიც ერთმანეთს ეჯიბრებიან მაღაზიის თაროებზე. გაყიდვების მაჩვენებლებიც ამას ადასტურებს, რადგან უმეტესობა მომხმარებლის მიერ წიგნის შეძენის დროს ჯერ კიდევ ყდით გადაწყვეტილი იქნება. გამომცემლობები პოულობენ ამ ტექნოლოგიის გამოყენების ახალ გზებს, რათა მკითხველი დაბრუნდეს და კვლავ წაიკითხოს მეტი. დამატებითი ტექსტური ელემენტი მნიშვნელოვნად მონაწილეობს იმაში, აიღებს თუ არა ადამიანი კონკრეტულ წიგნს ან გადავა სხვაზე.

Ბიზნეს ბარათის პერსონალიზაცია მეტალურგიული დასრულებებით

Უფრო მეტი კომპანია აქცევს ყურადღებას ცხელ ტიპოგრაფიაზე, როდესაც საჭირო გახლავთ მაღალი ხარისხის ვიზიტკარტების დამზადება, რომლებიც ადამიანებს სამყაროში დასჩენს. მეტალური საფარის დამატება ამ ბარათებს აცხოვრებს კონფერენციებზე და გამოფენებზე, რაც ქმნის პროფესიონალურ და ლუქსურ შთაბეჭდილებას. ჩვეულებრივი ბეჭდვის ტექნიკებთან შედარებით, ცხელი ბეჭდვის მეთოდით დამზადებული ვიზიტკარტები უბრალოდ განსხვავებულად გამოიყურება. ისინი უმაღლესი ხარისხისაა და ასევე ხელმისაწვდომია სხვადასხვა სპეციალური საფარით. ბევრი კომპანია ამ ინვესტიციას ღირებულად მიიჩნევს, როდესაც მნიშვნელოვანია ბრენდის არსებობის შესაქმნელად.

Გრძელების კარტების დასრულების ტრენდები

Ბოჭკოვანი სტამპვა ბოლო დროს საკმაოდ პოპულარული გახდა სასწაგრე ბარათების ბიზნესში, რაც ამ მარტივ შეტყობინებებს დამატებით ელეგანტურობის შეხებას აძლევს. ხალხი უფრო მეტად ილახა იმ ბარათებისკენ, რომლებზეც ასეთი ლუქსური საფარია, რაც იმით ასე განსხვავებულად გრძნობინებს მათ, როცა ისინი გადაეცემა. ეს ვლინდება სხვადასხვა ტიპის ბარათებშიც — უამრავი დღესასწაულის ბარათი ნამდვილად გამოირჩევა, მაგრამ ამჟამად ასეთი სტამპირებული ეფექტი ქურდის წერილებსა და კორპორატიულ მადლობებშიც კი გამოიყენება. ბაზრის კვლევები აჩვენებს, რომ უფრო მეტი მომხმარებელი სურს, რომ მათი ბარათები გამოირჩეოდეს დანარჩენიდან, ხშირად არჩევანს აკეთებს რაღაც განსხვავებულისაკენ, სადაც ბოჭკოვან სტამპვას მნიშვნელოვანი როლი აქვს. ეს არ არის მხოლოდ დროებითი მოდა; ამ დროისთვის ეს უკვე სტანდარტულ მოლოდინად იქცა მრავალ საჩუქრის გაცემის შემთხვევაში.

Ხელიკრული

Როგორი მასალები შეიძლება გამოიყენონ ხოთ სტემპინგის მაशინებში?

Ამ კონტექსტში, ბოჭკოვანი სტამპვის მანქანები ძირითადად გამოიყენება ქაღალდის სხვადასხვა სახის მასალებზე, მათ შორის თხელ ქაღალდზე, სხვადასხვა სიმკვრივის კარტონზე და გამოყენებულ სპეციალურ ქაღალდის ფილაზე შეფუთვისა და ბეჭდვის მიზნით.

Როგორ ახდენს ცხოვრების სტამპირება გამოწვევის ინდუსტრიას?

Ცხელი სტამპვარდება ამაღლებს ქაღალდის შეფუთვის ვიზუალურ მიმზიდველობას, განსაკუთრებით ლუქსის ბრენდებისთვის, რადგან უზრუნველყოფს უნიკალურ და პრემიუმ დიზაინს, ხოლო სხვა ბეჭდვის მეთოდებთან შედარებით ნაკლები ნაგავის წარმოქმნით უზრუნველყოფს მდგრადობის მიზნების მიღწევას.

Რატომ არის ცხოვრების სტამპირება სასურველი მაღალ მოცულობის ლაბელების წარმოებაში?

Ცხელი სტამპვარდება უზრუნველყოფს ეფექტურობას და მაღალ ხარისხს მაღალი მოცულობის ქაღალდის ნიშნულების წარმოებაში, რაც უზრუნველყოფს მილიონობით ნიშნულზე ერთგვაროვან დეტალურობას და ფერის სტაბილურობას სიჩქარის შეუმცირებლად.